3D Printer Is the Future!

Humanity is familiar with 3D printers not long ago, because they have appeared only a few decades ago. But 3D printing has already widely used in various fields of human activity. This technology was introduced much earlier, but only in recent years with the help of 3D printers it has become almost perfect. During operation, the 3D printer alternately superimposes layers of a substance on each other in order to reproduce a given volume figures based on a virtual three-dimensional image.

The History of 3D printing

Creation of three-dimensional printers became especially important after appearing lathes and milling machines, which are considered to be the main precursors of three-dimensional printers. Even in the middle of the twentieth century, people thought about automated devices that would be able to create the object of any form from durable materials, such as metal or wood. It was during this period of time and was created the first 3D-printer that could be purchased for an enormous sum of money amounting to several tens or even hundreds of thousands of dollars.

In those days, 3d printer could print only a small number of simple parts, as this technology was still underdeveloped. It is also important that the first three-dimensional printing devices were not tiny and compact as modern. They were bulky and were used only by large enterprises, but small private firms could not purchase them because of the high cost and dimensions.

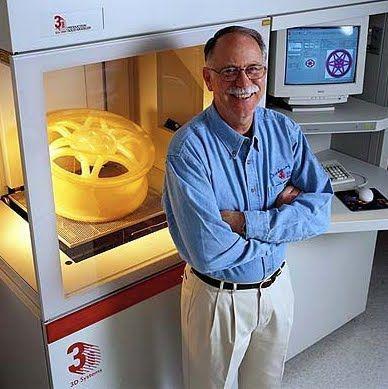

However, printing on a 3D printer at that time had become necessary and for private entrepreneurs, so developers had begun active work to design smaller and much more efficient devices for three-dimensional printing. And soon variety of devices appeared on the world market. 3D printer, the photo of which you can see below, is dated 1988. It was created by "3D Systems", and very soon, this model had become widely used among users worldwide.

It is noteworthy that as a material for creating three-dimensional objects were used chocolate, wood or plastic "ABC". Today the list of such materials has become much wider, and three-dimensional printing is used almost everywhere.

How it all began

First implementation of recreating objects and figures in the three-dimensional plane engaged the American scientist Charles Hull, back in early 1948. That's the name of this person is related to develop the technology of 3D printing using so-called photopolymerizable composition. In those early years, scientists have named this technology stereolithography. Hull was able to patent his creation only in 1986, despite numerous successful researches. After that, the inventor has not lost a minute of his time and opened a company called "3D System".

This company has developed the world's first 3D printer, which was then called stereolithographic installation. Of course, you want to know how works 3D printer, but more about this, we'll talk a little later. Following the procedure, which was developed by Hull, first of all, the objects to be re-created were modeled on a computer with special software. After that, were grown subtle layers of photopolymer liquid composition and placed to the ever-moving platform. Then, applying these thinnest layers on each other were formed the desired object. It is known that each such layer was not more than 0.2 millimeters in thickness. It was the first 3D printer of industrial type.

Charles Hull was not going to rest on laurels, therefore he had given some still being tested models of printers to his best customers. By this way it was possible to find out the weaknesses, which were soon eliminated or modified. As a result, already in 1988 Corporation "3D System" has released a series of stereolithography devices. 3D printer business has become a matter of his life, earning him millions of dollars.

3D printer, model type SLA-250, photo of which you can see below, quickly became popular in a variety of industrial applications. Some cunning persons, not wanting to spend mad amounts of money on the purchase of such expensive equipment, tried to collect a 3D printer with their hands, but most attempts were unsuccessful. Although industrial printers were widely used, the need for simplified and miniaturized models was increasingly apparent.

Picture 2. 3D printer, model type SLA-250

Soon "3D System" delighted its customers and with such devices. Updated miniature 3D printers have conquered the world market in 2012; they were much smaller than their industrial counterparts. To date, three-dimensional printers are available to almost anyone who wants. If you want to buy a 3D printer in Moscow or any other city, you can do it or in specialty stores or over the Internet. The main thing is to know how to choose the appropriate 3D printer and how to exploit such a device. We will talk about this in more details in the following articles.

Picture 3. Consumer three-dimensional printers

Other three-dimensional printing technologies

It is known that not only one Charles Hull studied issues relating to three-dimensional printing. That is why today humanity knows not only stereolithographic technology for recreating three-dimensional objects and parts:

1) LOM – recreation of three-dimensional objects from layers of sheet materialThis method of 3D printing was invented by Michael Feygin in 1985, when mister Hull has not yet received his patent. To understand how such a 3D printer works, you need to look at three-dimensional image of the relief of the planet on which levels with the same heights are shown in one color. Laminated object manufacturing (LOM) is a method of 3D printing, which uses a continuous sheet of material — plastic, paper or (less commonly) metal. Plastic and paper build materials are often coated with an adhesive. To form an object, a heated roller is passed over the sheet of material on the build platform, melting its adhesive and pressing it onto the platform.

Picture 4. Model, made by LOM technology

Previously such models were creating manually over the several days or several weeks, depending on the complexity and size of the object. The method invented by Feygin had greatly simplified the process, so the three-dimensional objects could be made in just a couple of hours. However it is difficult to call perfect this technology, as the models are obtained too rough and quite fragile. And very often the problem of three-dimensional objects created in this manner is their frequent bundle.

2) SLS – Selective Laser SinteringThis method was first proposed by Carl Deckard in 1986. Selective laser sintering uses lasers as its power source to sinter powdered material, binding it together to create a solid structure.

Powder in a small working chamber is heated to a temperature close to the melting point, and then leveled, and after that laser beam draws on it the desired circuit. The powder particles melt and sinter with one another and with the previous layer (hence the name of the method). Then the platform is lowered to one layer thickness, and a new layer of powder is leveled, and the process is repeated until the model will not be completely finished.

Surface of the made models is always rough and porous. Compared with other methods, SLS can produce parts from a relatively wide range of commercially available powder materials, such as: ceramics, various metals, polymeric materials and wax. The main drawback of such equipment can be considered, only the need for a thorough cleaning of the working chamber after each session in the construction of three-dimensional models of different materials.

It is also interesting that the 3D printer of this type can print simultaneously multiple objects.

Picture 5. Shaped objects made by selective laser sintering technology

This technology is very closely associated with photocopying. It appeared first in 1987, thanks to the achievements’ of the Israeli company "Cubital".

At the beginning, mask is forming on the charged glass plate in this method of three-dimensional printing. Then the mask is placed over the thin layer of photopolymer and exposed using a beam of ultraviolet light. As a result, photopolymer substance solidifies on exposed areas, and the excess material can be easily removed from the work site. This cycle is repeated until the model is ready. The advantage of this device of three-dimensional printing, is user's ability at any time to stop the workflow for quality control of work and fix any defects.

However, it should be mentioned that the cost of 3D printers working on the basis of this method is high enough. The reason is using of expensive and rare polymeric compounds. Such 3D printer can be bought for 450-500 thousand dollars. Small business clearly cannot cope with such financial costs. In addition, this device requires constant operator control and creates a lot of noise. Likely to purchase such a 3D printer in Moscow you will not be able, but, perhaps, it is no need.

4) FDM – Fused Deposition ModelingFounder and inventor of the idea of this method, three-dimensional printing is considered to be Scott Crump. In 1988 he made such 3D printer with his own hands and received a patent.

This device works thanks to a dedicated print head, which contains the necessary material in molten form. This can be a wax, plastic or even metal. It is important that this substance would be constantly warmed to the melting point. The head releases a thin thread of building material that evenly placed on the working platform. When the first layer is completed, the working platform is lowered below for easier application of subsequent material layers.

This technology reached unprecedented popularity in 1991-1993, when Crump began mass production of his invention, founding the company "Stratasys". It was possible to buy a three-dimensional printer of such production already for 50,000 U.S. dollars. At present day, it costs from 100 to 200 thousand dollars.

Picture 6. 3D printer based on FDM technology

Now three-dimensional printing is widely used not only in industry and construction, but also gradually takes its stable position in medicine and cooking. Each of the above methods of three-dimensional printing found a place in a particular area, but the most promising and relevant still remains stereolithography, because it is not limited to the use of specific materials for the construction of figures. Many people believe that 3D printers are our future, and developers every year make them better and better, opening up new opportunities and destroying stereotypes of impossibility.